Learn about HVAC Installation

Outline:

– The role of HVAC installation in comfort, health, and energy costs

– How heating and cooling systems work and how they differ

– Planning and sizing, from load calculations to duct design

– Air conditioning installation: steps, safety, and commissioning

– Efficiency, indoor air quality, smart controls, and ownership costs

– Conclusion and next steps for confident decision-making

Introduction

HVAC installation sits at the intersection of comfort, health, and long-term value. A thoughtfully designed heating and cooling setup moderates temperature and humidity, filters pollutants, and does it all with reasonable energy use. When the system is mismatched to the home, the results are predictable: rooms that never quite feel right, equipment that cycles too often, and utility bills that creep upward. Conversely, a right-sized, well-installed system can stabilize indoor conditions through seasonal swings, reduce strain on components, and maintain consistent airflow where you need it most. This guide brings clarity to the process, from understanding system types to following the steps of air conditioning installation, and closes with practical advice for keeping performance strong year after year.

Foundations: How Heating and Cooling Systems Work

Heating, ventilation, and air conditioning is a coordinated set of components designed to supply conditioned air at the right temperature, humidity, and cleanliness. The central actors include equipment that adds or removes heat, a distribution network that moves air, a control strategy that tells everything what to do, and a ventilation layer that brings in fresh air and exhausts stale air. Whether your space relies on ducted distribution or localized heads, the physics under the hood follow familiar paths: heat moves from warmer to cooler regions, pressure and temperature change with compression and expansion, and fans drive air through resistance created by ducts, filters, and coils.

Common system configurations include several archetypes, each suited to specific constraints and goals. A central split air conditioner pairs an outdoor condensing unit with an indoor evaporator coil to remove heat during summer; in cooler months, a separate furnace or air handler takes over heating. Heat pumps look similar, but their refrigeration cycle can reverse, providing both cooling and heating from a single set of components. Ductless systems provide zoned comfort without ductwork and are often favored for additions, retrofits, or spaces with limited mechanical chases. Packaged units combine components into a single cabinet for rooftops or tight yards, while hydronic or radiant systems decouple air distribution from heat delivery, often needing separate solutions for cooling.

If you compare performance metrics, you’ll notice that cooling efficiency is often expressed as SEER2 or EER2, while heating efficiency for heat pumps appears as HSPF2 or coefficient of performance (COP). Typical entry ratings start around the mid-teens for SEER2, with higher tiers climbing well above that; heat pump HSPF2 values commonly range from the upper single digits to low double digits, meaning more heat per unit of electricity across a season. Furnaces are rated with AFUE, where modern high-efficiency designs can exceed 95 percent under standardized testing. Noise is another practical detail: many systems target outdoor sound levels in the mid-50s to low-60s decibels under normal operation, though exact numbers vary with capacity and fan speed. Real-world comfort also hinges on air delivery, and ducts matter; leakage in older homes can run into double-digit percentages of total airflow, so a carefully sealed, balanced distribution network is a critical co-star in the comfort story.

To ground this bird’s-eye view, here are quick contrasts many households consider:

– Heat pump versus furnace plus AC: single system that both heats and cools versus dedicated heating equipment paired with separate cooling.

– Ducted versus ductless: whole-home distribution through hidden pathways versus targeted zones with visible indoor heads.

– Single-stage versus variable-capacity: simple on/off cycles versus quieter, longer, lower-speed runs that can smooth temperatures and reduce short cycling.

Planning and Sizing: From Load Calculations to Duct Design

Before a wrench touches copper or a screw bites into sheet metal, planning sets the trajectory. A proper load calculation estimates how much heat your building gains in summer and loses in winter. That number depends on climate, orientation, insulation levels, window performance and shading, air leakage, internal gains from people and appliances, and even how the home is used day to day. The goal is to size equipment and ducts to meet demand without overshooting. Oversized cooling can chill the air quickly but fail to remove sufficient moisture, leaving rooms clammy; oversized heating can short-cycle and wear parts prematurely. Undersized systems struggle on the most extreme days, running constantly while still leaving occupants uncomfortable. Good design threads the needle.

Industry-standard methods translate building characteristics into numbers for equipment selection and duct sizing. A comprehensive approach coordinates three pieces: a load model to predict heating and cooling needs, a selection process to match equipment to those needs at real operating conditions, and a duct design to deliver airflow quietly and efficiently. Designers pay attention to static pressure, friction rates, trunk-and-branch layouts, and register placement. Returns are sized to keep air speeds in a comfortable range and to reduce pressure imbalances between rooms. In many homes, a pressure map reveals which interior doors starve rooms of return air, prompting added jump ducts or transfer grilles to maintain circulation when doors are closed.

Ventilation planning belongs in the same conversation. Fresh air can be handled by dedicated ventilators that exchange heat and, in some models, moisture between incoming and outgoing streams. The targeted intake rate usually scales with floor area and occupants and is often guided by national standards adopted into local codes. Rather than relying on incidental leakage, a balanced system delivers a predictable supply of outdoor air and exhausts stale air from kitchens and baths, helping control odors, carbon dioxide, and indoor pollutants. The ventilation device must be integrated into the broader plan so that total static pressure remains within the blower’s capability, filters maintain reasonable pressure drop, and condensation is managed safely.

Here is a condensed checklist that underscores the planning priorities:

– Measure, don’t guess: use a recognized load method rather than rule-of-thumb tonnage per square foot.

– Design airflow: set target cubic feet per minute per room and size ducts to hit those numbers at acceptable static pressure.

– Coordinate ventilation: supply and exhaust must complement the HVAC plan, not fight it.

– Anticipate maintenance: allow space to service filters, coils, and condensate lines, with clear, labeled access.

Air Conditioning Installation: Step-by-Step and Quality Checks

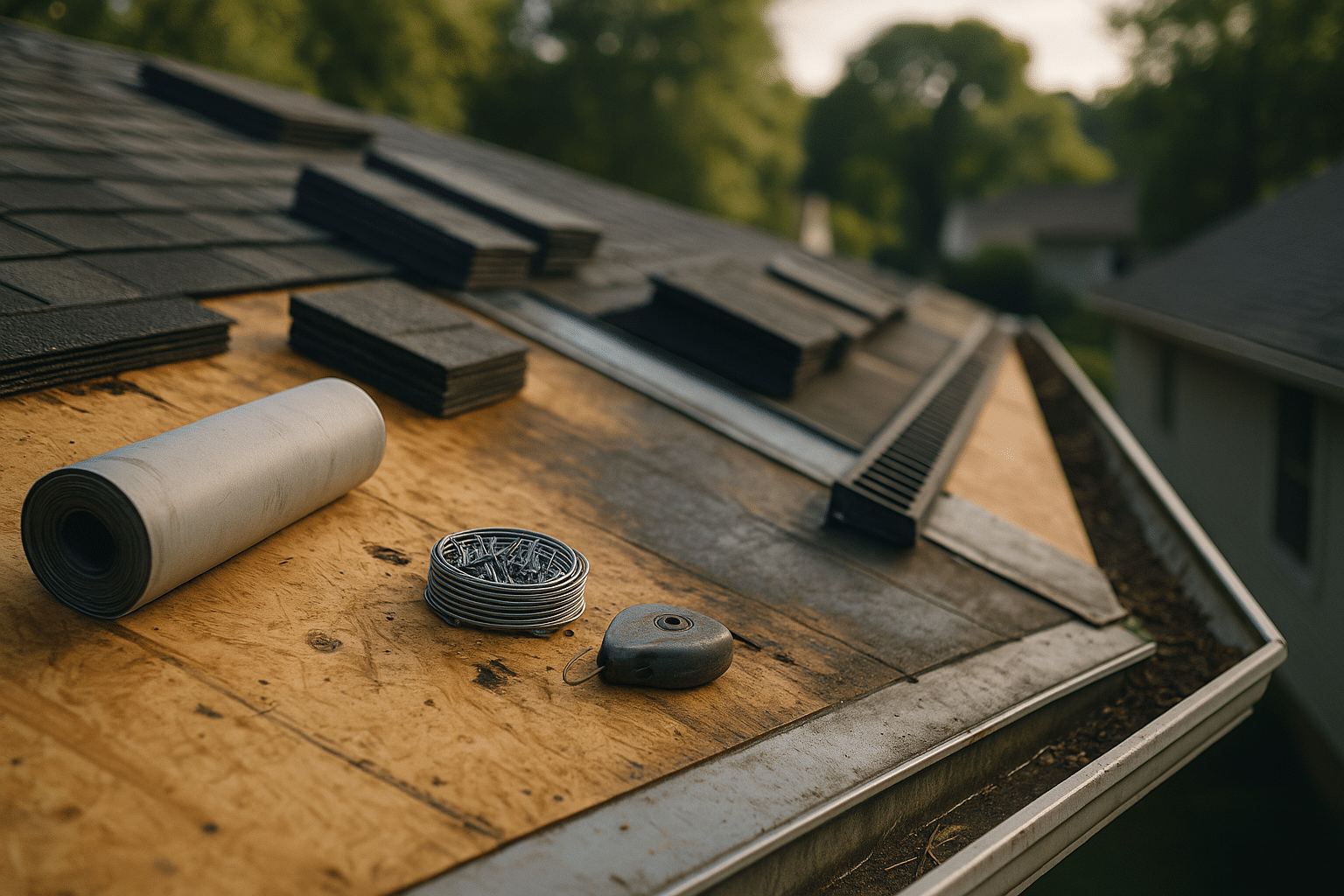

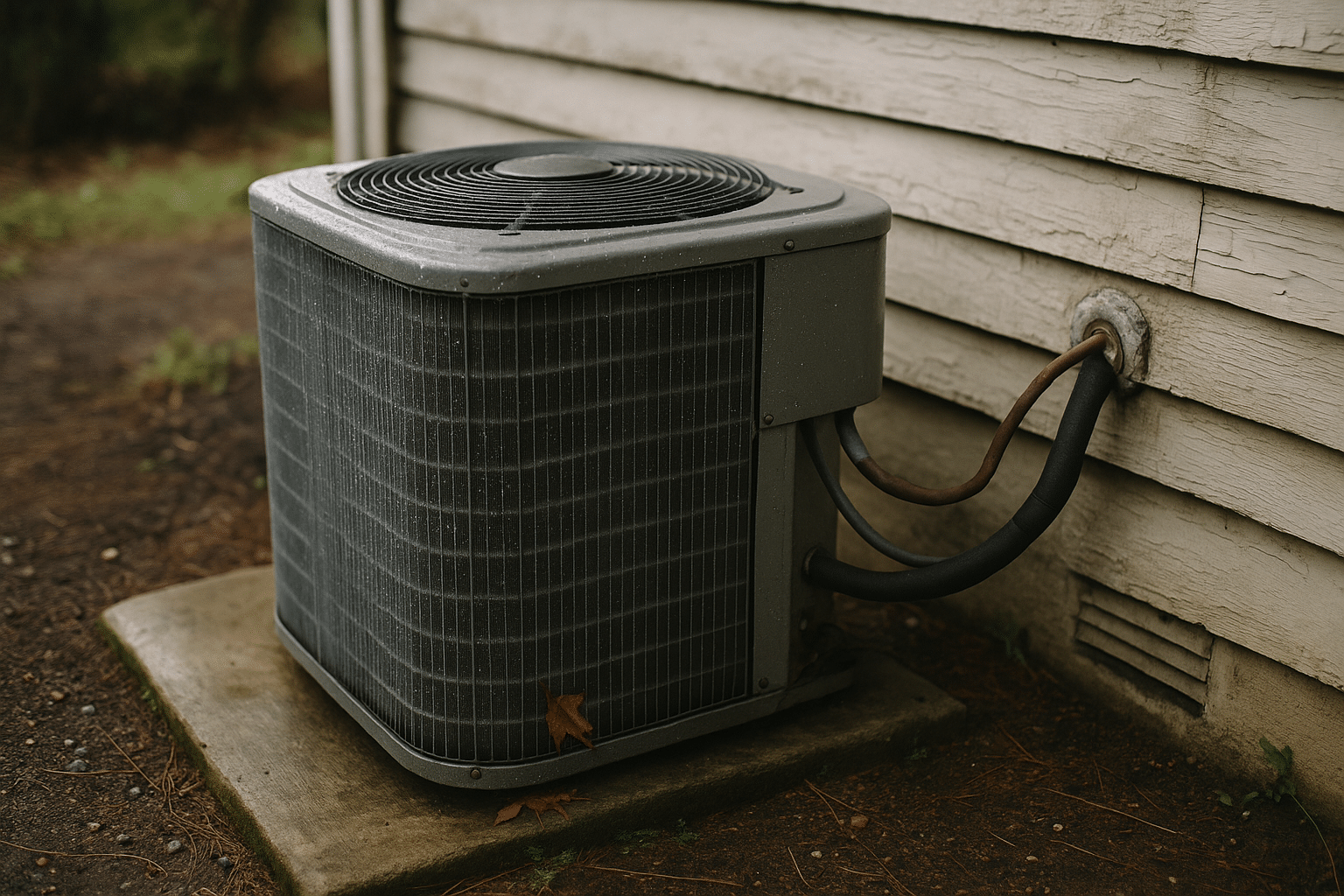

Air conditioning installation is a choreography of placement, refrigeration, electrical work, drainage, sealing, and testing. It starts with site preparation: the outdoor unit needs a level pad with good drainage and clear air paths on all sides. Line-set routing is planned to minimize bends and protect against damage, with sleeves or covers where it passes through walls. Inside, the evaporator coil is installed in the air handler or above a furnace, and a secondary drain pan is added where leaks could cause damage. Condensate lines are sloped to drain by gravity when possible, outfitted with cleanouts and traps as required by code, and routed to an approved termination. If a condensate pump is necessary, it receives its own check valve and a way to signal an overflow condition.

The refrigeration circuit demands careful workmanship. Copper is cut cleanly, deburred, and joined with brazed connections while an inert gas purges the lines to minimize scale. After connections are complete, the system is pressure-tested, commonly with dry nitrogen, to confirm tightness before evacuation. Vacuum pumps draw down moisture and air, with targets often reaching deep vacuum levels verified by an accurate gauge; a tight system should hold steady. Only then does the technician release or weigh in the refrigerant charge according to the manufacturer’s tables that account for line length, coil size, and operating mode. Electrical connections are landed with attention to wire gauges, overcurrent protection, and proper disconnect placement. Thermostat and control wiring is verified end to end, with labeling to reduce confusion during future service.

Commissioning transforms an installation into a working, validated system. Airflow is measured and balanced; pressures, temperatures, and superheat/subcool are recorded under defined conditions; and voltage and amperage are checked against nameplate values. Filters are installed, and any bypass paths are sealed so air passes through the intended media. Duct leakage is tested where required, and accessible joints are sealed with mastic or UL-listed tape. Outdoor clearances are confirmed one last time, debris is removed, and coil guards are straightened. The system runs long enough to reach stable operation, and a punch list documents the readings. A copy goes to the owner, who also receives instruction on filter changes, thermostat settings, and what normal sounds and drainage look like.

Two practical notes deserve emphasis:

– Permits and inspections: many jurisdictions require a permit and a final sign-off that includes electrical, mechanical, and sometimes energy code checks.

– Safety: refrigerants can displace oxygen in confined spaces, brazing involves open flame, and electrical circuits demand lockout procedures; trained professionals follow safety protocols to reduce risk.

Efficiency, Air Quality, Smart Controls, and Ownership Costs

Energy performance and indoor air quality are twin pillars of a satisfying HVAC outcome, and both influence the total cost of ownership. Efficiency starts with the building shell—insulation and air sealing reduce the load before it reaches the equipment. On the mechanical side, higher seasonal efficiency ratings, variable-capacity compressors, and efficient blower motors can trim kilowatt-hours while smoothing comfort. As a rough intuition, every step up in seasonal efficiency can shave a noticeable slice off cooling energy use in many climates, though the exact savings depend on local weather, electricity rates, and how the system is operated. Utility programs or regional incentives sometimes reward higher efficiency installs, which can shorten payback periods.

Air quality hinges on filtration, humidity control, and fresh air. Filters rated in the MERV 8 to 13 range can capture a substantial share of common particulates; moving up the scale usually means higher pressure drop, so the filter rack and blower capacity should be sized accordingly. Maintaining indoor relative humidity roughly between 30 and 50 percent tends to improve comfort and can help curb dust mites and mold growth. In humid regions, air conditioners and heat pumps provide latent (moisture) removal when run times are adequate; variable-speed equipment can help by maintaining coil contact time. Where ventilation is added, energy recovery units can reduce the penalty of conditioning outdoor air by transferring heat—and sometimes moisture—between streams.

Smart controls can nudge performance in the right direction. Programmable thermostats that are actually programmed can cut runtime in unoccupied periods, and advanced models can modulate blower and compressor speeds to match demand. Zoning can deliver targeted airflow to different areas, though it must be designed carefully to avoid exceeding allowable static pressure when only small zones call. Beyond energy savings, controls offer convenience: remote access, alerts for filter changes or abnormal operation, and trend data that helps catch small issues before they grow.

Costs extend beyond the invoice on day one. A new central air conditioner or heat pump installation can range widely based on home size, distribution complexity, efficiency level, refrigerant line lengths, and whether ductwork is new or being repaired. Duct sealing and balancing add cost but can pay dividends in quieter operation and even temperatures. Filters, periodic coil cleaning, and seasonal checkups are modest line items compared to major repairs. Many manufacturers offer parts warranties measured in years, with labor coverage defined by the contractor; registering the equipment on time can enhance coverage. Over a typical life expectancy—often around 12 to 15 years for many cooling systems and longer for some heating appliances—thoughtful maintenance can sustain efficiency and head off failures.

When prioritizing upgrades, a simple roadmap helps:

– Fix the envelope first where practical; it shrinks the equipment you need.

– Choose equipment that aligns with your climate and usage patterns, not just nameplate ratings.

– Invest in duct sealing and balancing; airflow is the quiet hero of comfort and efficiency.

– Set up controls you will actually use; automated schedules and reasonable setpoints save energy without fuss.

Conclusion and Next Steps: Making a Confident HVAC Decision

If you are weighing a new HVAC installation, begin with clarity on outcomes: steadier comfort, predictable bills, and cleaner indoor air. That clarity will guide choices at every fork in the road—system type, capacity, duct approach, ventilation strategy, and controls. Start by documenting your home’s particulars: square footage, insulation levels, window areas and shading, problem rooms, and any moisture or air quality concerns. Ask for a written load calculation and a design summary that lists target airflow per room, planned static pressure, filter size, and ventilation rates. This information helps you compare proposals on equal footing and reduces reliance on vague rules of thumb.

As you review options, picture how you live. If the home is occupied throughout the day, quieter, longer, lower-speed operation may be worth the premium because it keeps conditions even and can enhance dehumidification. If you travel often or rent the space, remote monitoring and alerts can prevent small issues—like a clogged condensate line—from becoming expensive repairs. In mixed climates, a heat pump paired with supplemental heat might make sense for most of the year; in colder zones, careful selection of low-ambient performance and backup strategies ensures reliable heating during cold snaps. If ducts are older or suspect, budget time for sealing, adding returns, or correcting undersized runs; a well-installed high-efficiency unit cannot overcome chronic airflow bottlenecks.

Prepare for ownership with simple habits that preserve performance. Replace or clean filters on a schedule that reflects actual usage and dust levels. Keep outdoor coils free of leaves, yard clippings, and snow drifts, and make sure the unit has breathing room. Glance at the condensate drain at the start of each season to confirm steady flow and no leaks near the air handler. Set realistic thermostat schedules and resist large, frequent setpoint swings that can increase runtime without meaningfully improving comfort. Consider a spring check focused on cooling and a fall check focused on heating; these visits can catch issues like pitted contacts, weak capacitors, or slow fan motors before peak season.

Finally, make documentation your ally. Keep installation records, commissioning data, model and serial numbers, warranty confirmations, and service notes in one place. This paper trail speeds future work, supports warranty claims, and signals that the system has been cared for. With a measured plan, a clear scope, and follow-through on maintenance, your HVAC installation can deliver quiet, even comfort and resilient performance season after season—without drama or surprises.