Learn about Plumbing supplies

Outline

– Pipes and tubes: materials, sizing, pressure/temperature ratings, and service life

– Fittings, valves, and connectors: joint types, reliability, and maintenance

– Fixtures and water efficiency: performance metrics, safety standards, and supply lines

– Drainage, waste, and venting (DWV): slopes, venting strategies, and noise control

– Tools, sealants, and installation essentials: step-by-step habits that prevent leaks

Pipes and Tubes: Materials, Sizing, and Longevity

Successful plumbing starts with understanding the pipe carrying the water. Materials differ in cost, durability, temperature tolerance, ease of installation, and environmental impact, and those differences shape performance for decades. Most homes combine several materials: copper for durability, PEX for flexibility, CPVC for hot water handling, and PVC for drain, waste, and vent lines. Choosing wisely can reduce leaks, maintain water quality, and create a system that can be serviced without drama.

PEX (cross-linked polyethylene) has become a go-to for many projects because it bends around corners, reduces the number of fittings, and resists scale buildup. Typical ratings are about 160 psi at 73°F, 100 psi at 180°F, and 80 psi at 200°F, making it suitable for domestic hot water when installed per manufacturer guidance. Oxygen-barrier versions are used in hydronic heating loops, while non-barrier types serve domestic water. Because it expands, PEX tolerates brief freezing far better than rigid pipe, though winterizing and insulation remain essential.

Copper remains a highly regarded choice thanks to its longevity and heat resistance. Types K, L, and M indicate wall thickness, with K being thickest. Soldered joints, when properly cleaned and fluxed, can last for generations, and copper tolerates high temperatures that might soften plastics. However, it is less forgiving to freezing and typically costs more in both material and labor. Water chemistry matters: aggressive, low-pH water can corrode copper, so municipal reports or a simple lab test help inform material selection.

CPVC is a chlorinated PVC designed for hot and cold potable water. It is rigid, solvent-welded, and often chosen in regions where copper is expensive. It handles typical domestic hot water temperatures, but installers should observe expansion gaps, support spacing, and primer/cement cure times to avoid brittle failures. For drains and vents, PVC or ABS are common. These light, solvent-welded pipes are easy to cut and assemble and resist many household chemicals. Schedule 40 PVC is typical for residential DWV and is sized by nominal diameter, while copper tubing uses nominal sizes based on outside diameter conventions.

When comparing materials, consider:

– Life-cycle cost: material price plus labor, maintenance, and expected service life

– Water quality: compatibility with local pH and mineral content

– Accessibility: future repairs, availability of compatible fittings, and code acceptance

– Noise and heat: copper transmits heat and sound; plastics dampen vibrations and lose less heat in short runs

Sizing matters too. Undersized lines can cause pressure drops when multiple fixtures run, while oversized hot lines waste energy in stand-by cooling. A balanced layout, with trunk-and-branch or home-run manifolds for PEX, keeps flow consistent and simplifies isolation. Always check local code for minimum sizes, required shutoffs, and insulation rules.

Fittings, Valves, and Connectors: Making Reliable Joints

The hidden artistry of plumbing lives in its joints. Fittings guide direction, adapt sizes, and connect different materials, while valves control flow and isolate sections for service. Thoughtful selection prevents leaks, minimizes turbulence, and makes future maintenance straightforward. Skimping here often turns small service calls into wall-opening headaches.

Common fitting families include sweat (soldered) copper, solvent-welded PVC/CPVC, crimped or expansion PEX, compression, and push-to-connect. Soldered copper, when properly cleaned and heated, yields robust, permanent connections. PEX systems use either copper rings crimped with a gauge-verified tool or expansion sleeves that contract for a tight seal; both methods are code-accepted and reliable when executed correctly. Compression fittings shine on fixture shutoffs and supply lines where disassembly may be needed, while push-to-connect styles offer fast repairs, especially in tight spaces or wet conditions, though they should be protected from movement and installed with correct pipe insertion depth.

Valves deserve careful attention. Ball valves are widely favored for their quarter-turn action, full flow, and durability. Gate valves have a rising stem and are better suited for infrequent use; they can seize in older systems. Globe valves allow more precise throttling but reduce flow; mixing and thermostatic valves regulate temperature for safety and comfort. Check valves prevent backflow, an important defense when pumps, boilers, or irrigation tie into domestic lines. In many jurisdictions, backflow prevention assemblies are required where cross-connections exist, and periodic testing is mandated.

Adapters bridge materials: copper-to-PEX transitions, threaded-to-sweat unions, and dielectric unions when joining copper to steel to reduce galvanic corrosion. Flexible connectors with stainless overbraid help isolate vibrations at appliances, while rigid supplies maintain crisp geometry under sinks. Pay attention to thread standards: tapered pipe threads seal on the thread with sealant, while straight threads rely on washers or o-rings. Mixing the two leads to leaks or cracked fittings.

Consider these reliability habits:

– Use full-port ball valves for main shutoffs and critical branches

– Add accessible isolation valves at water heaters, major fixtures, and exterior lines

– Support transitions with proper brackets to avoid stress on joints

– Pressure-test new work before closing walls; even a minor drip compounds damage over time

Finally, leave a “service map” in the mechanical room: a simple diagram of valve locations and the circuits they control. This small touch transforms emergencies into orderly shutoffs and keeps future repairs measured and calm.

Fixtures, Supply Lines, and Water Efficiency

Fixtures turn networked pipes into everyday comfort, and small choices here have outsized effects on water use and user experience. Flow rates and flush volumes are measured and standardized, making it easier to compare performance across products and styles. A sensible approach pairs durable valves and safe materials with efficient aerators and sprays that feel generous without wasting water.

Common benchmarks help frame decisions. In many regions, showerheads are limited to 2.5 gallons per minute (gpm) at 80 psi, while high-efficiency models often target about 2.0 gpm. Bathroom sink faucets frequently range around 1.2 gpm, with kitchen faucets often near 1.8 gpm. Toilets have a federal maximum of 1.6 gallons per flush (gpf), and high-efficiency designs achieve roughly 1.28 gpf while maintaining reliable clearances. These numbers are meaningful: cutting a shower from 2.5 to 2.0 gpm can save thousands of gallons annually in a busy household, and efficient toilets can drop daily consumption with no behavioral change.

Quality supply lines and stop valves are unsung heroes. Braided stainless supplies resist kinking and help absorb minor movement, while rigid lines offer a clean look if the geometry lines up perfectly. Shutoff valves should be lead-free and operable by hand, with quarter-turn designs favored for quick isolation. Look for certifications indicating compliance with standards for potable water contact; these reduce concerns about leaching and ensure materials meet public health criteria.

For water heaters and mixing valves, anti-scald protection is vital. Thermostatic mixing valves blend hot and cold to a safe delivery temperature, often set near 120°F. Laundry and utility sinks benefit from robust, replaceable cartridges and easy-clean aerators. Filters and sediment traps at sensitive fixtures, such as pull-down kitchen sprayers, extend service life and maintain flow.

Practical fixture tips:

– Match aerators to real use: 1.2 gpm for handwashing, higher for pot-filling if needed

– Choose adjustable spray patterns that maintain rinsing efficiency at lower flow

– Add isolation valves at each fixture for painless service

– Use supply lines with integral gaskets and replace them proactively every 5–10 years

Small leaks add up. A single drip per second can waste more than 3,000 gallons a year, and an unnoticed toilet flapper leak can quietly multiply that number. Regularly inspect under-sink connections, angle stops, and the base of toilets and sinks for moisture rings or mineral tracks. A few minutes with a flashlight can save a drywall repair and a Saturday afternoon.

Drainage, Waste, and Venting (DWV): Quiet, Code-Compliant Flow

Supplying clean water is only half the story; removing used water and air is where dwellings stay sanitary and comfortable. DWV systems rely on gravity, smooth interior walls, and correctly sized vents to prevent siphoning of traps. When drains are quiet and traps stay sealed, rooms stay odor-free and—most importantly—safe.

PVC and ABS dominate residential DWV because they are light, easy to cut, and solvent-weld into airtight runs. For most residential branches, a slope near 1/4 inch per foot balances velocity: enough fall to carry solids, not so much that water outruns them and leaves debris behind. Larger diameter mains sometimes allow 1/8 inch per foot, but local code governs specifics. Each fixture needs a trap to block sewer gas, and vents must provide air behind moving water to prevent trap siphoning. Without adequate venting, you’ll hear gurgling and smell trouble.

Vent strategies include individual vents for nearby fixtures, common vents that serve two fixtures back-to-back, and wet venting where a properly sized pipe carries both drainage and vent air for a limited group. A master vent stack typically exits the roof; keeping its termination clear of snow, leaves, and nests avoids slow drains and odor complaints. In some jurisdictions, air admittance valves are permitted for tricky remodels, but they must remain accessible and cannot replace required stack vents.

Cleanouts at strategic points—base of stacks, building drain transitions, and long horizontal runs—turn blockages into manageable chores. Long-radius bends reduce clog potential and noise by easing flow direction changes. Where floor drain traps risk drying out, trap primers or deep-seal traps help maintain a water barrier. Consider sound control in multistory buildings: heavier pipe walls, resilient hangers, and lagging can tame the midnight flush.

Useful DWV checkpoints:

– Maintain consistent slope and avoid sags by adding hangers per code spacing

– Keep vent runs rising, minimize horizontal runs below flood rims

– Use long-sweep fittings on horizontals to ease flow and maintenance

– Provide accessible cleanouts at changes of direction and at key distances

Before closing walls, run a water test on the stack or a low-pressure air test if permitted. Even tiny solvent-welding misses reveal themselves, and fixing them now beats cutting finished tile later. The reward for careful DWV work is silence: no gurgles, no odors, just a system that disappears into the background.

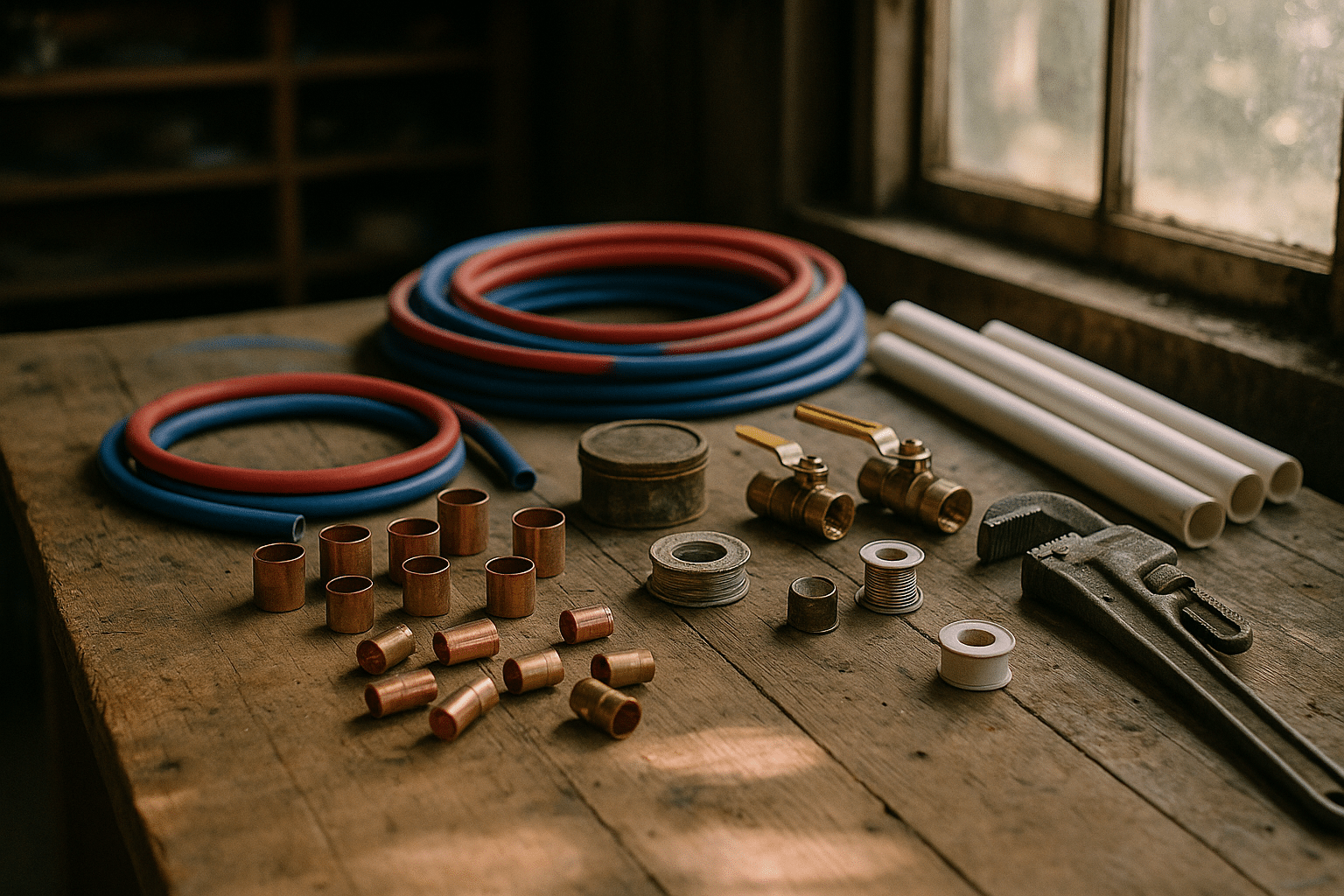

Tools, Sealants, and Installation Essentials

Plumbing rewards methodical habits. Right tools and sealants produce joints that remain dry under pressure spikes, temperature swings, and seasonal movement. A small investment in preparation beats chasing a hidden drip behind fresh paint, and a measured workflow brings calm to even hurried repairs.

Core tools include a tubing cutter for copper, a ratcheting PVC cutter, a fine-tooth saw for larger plastic, deburring tools, and a crimp or expansion tool set for PEX. Two adjustable wrenches handle opposing flats on fittings, while a basin wrench reaches behind sinks where knuckles fear to tread. A quality torch for soldering, heat-resistant pad, flux brushes, and emery cloth make copper work predictable. For safety, keep eye protection, gloves, and a fire-resistant spray bottle within reach, and use flame shields near combustibles.

Sealants are not one-size-fits-all. PTFE tape on tapered male threads offers a reliable primary seal; many installers layer 2–3 wraps in the direction of the threads to avoid unraveling during assembly. Pipe dope (thread sealant) complements PTFE on larger or imperfect threads and remains useful on metal fittings subject to vibration. Solvent cement and primer for PVC/CPVC chemically soften and fuse parts, creating a permanent bond—dry fitting first prevents misalignment. For compression and push-to-connect fittings, the seal relies on ferrules or o-rings; cleanliness, correct insertion depth, and square cuts are non-negotiable.

Installation habits that pay dividends:

– Dry-fit assemblies and mark orientation so final bonds land exactly where planned

– Support pipes at manufacturer-recommended intervals to prevent sag and joint stress

– Isolate dissimilar metals with dielectric unions to limit galvanic corrosion

– Insulate hot and cold lines where sweating, heat loss, or freeze risk is likely

Pressure testing is your truth-teller. Cap open ends, close valves as needed, and pressurize gradually while watching a gauge and inspecting with a bright light and a dry tissue. Even a faint weep leaves a telltale mark. For drains, a standing water test in tubs and showers confirms trap seals and drain assemblies. Document results with a quick photo of the gauge and the date; it becomes a project log and a confidence booster.

Finally, label main shutoffs and leave spare parts: a couple of supply lines, washers, and a roll of PTFE tape. Future you—or the next owner—will thank you during a midnight drip. Good plumbing fades from attention because it works, and these tools and techniques keep it that way.

Conclusion: Equip Your Project with Confidence

Choosing plumbing supplies is about more than grabbing a pipe and a valve; it’s matching material, method, and maintenance to your space and climate. With the right mix of PEX or copper for supply, PVC for drains, dependable valves, and certified fixtures, you create a system that is efficient, quiet, and straightforward to service. Build in isolation points, label shutoffs, and pressure-test before closing walls. Those small, disciplined steps turn projects into durable upgrades and keep comfort on tap for years to come.