Learn about Welding Training

Welding connects ideas to infrastructure, from modest repairs to complex structures that must perform under stress. Training is the bridge between curiosity and competence: a structured pathway that covers safety, processes, equipment, and the discipline to produce consistent results. Whether you want to change careers, add a high-demand skill, or refine techniques you already know, understanding how a solid program works will help you plan, budget, and practice with purpose.

Outline of this article:

– Why safety, physics, and mindset form the foundation of every weld

– A clear comparison of common processes and when each shines

– Essential tools, materials, and shop setup for trainees

– Training pathways, curriculum design, and certifications

– Careers, employability, and continuing education, plus a practical conclusion

Safety, Physics, and the Hands-On Mindset

Every strong training journey starts with safety and the basic physics of welding. You are guiding controlled heat to fuse metals, managing an electric arc or a flame, protecting molten puddles from atmospheric contamination, and letting the joint cool under predictable conditions. The hazards are real: ultraviolet radiation that can damage eyes and skin, airborne fumes produced by base metals and fillers, hot work near combustibles, electrical risks, and noise. This is why programs begin with protective habits: selecting the right shade for a helmet, using flame-resistant clothing, wearing gloves that balance dexterity and insulation, and ensuring proper ventilation or fume extraction. Fire prevention is routine, not optional, including having extinguishers at arm’s reach, clearing the area of flammables, and assigning a fire watch when needed.

Understanding the physics helps you read a weld pool the way an experienced driver reads a road. Arc length influences heat concentration; travel speed changes penetration and bead shape; angles affect gas coverage and spatter; and heat input controls distortion. Metals expand and contract as they heat and cool, so sequencing and fixturing counteract warping. This is where the mindset matters: patient setup leads to fewer surprises. Measuring, squaring, and tacking are not delays; they are the shortcuts to clean results. Trainees practice stringer beads on flat plate, then advance to fillets and multiple positions, learning how gravity pulls the puddle uphill and how to pause, weave, or adjust electrode angle to keep the toe of the weld anchored.

Core goals at this stage include:

– Build consistent body positioning and torch or electrode control for steady travel

– Learn to see the puddle rather than stare at the arc, adjusting by sight and sound

– Apply safe habits automatically, from cable management to post-weld cleanup

– Record settings, results, and observations so improvements are traceable

Quality control starts early. Visual inspection looks for undercut, porosity, lack of fusion, and irregular bead profiles. Simple bend or break tests on practice coupons demonstrate how internal flaws reveal themselves under stress. Trainees learn that a sound weld is often quiet—no fireworks, just a controlled pool that wets into clean edges and cools into a joint aligned with the drawing. Safety, physics, and habit stack into confidence, and confidence turns into repeatable results.

Processes Compared: Where Each Welding Method Excels

Effective training demystifies process choices. Shielded metal arc (often called stick) is rugged, portable, and forgiving of less-than-pristine surfaces. It thrives outdoors and on thicker materials, with electrodes that carry their own flux to shield the puddle. Gas metal arc (commonly known as wire-feed with a solid wire) offers speed and is favored for production and sheet-to-medium thickness work. It depends on shielding gas, making wind breaks and indoor use common. Flux-cored variations use tubular wire with flux, providing high deposition and better wind tolerance. Gas tungsten arc emphasizes precision and control, especially on thin materials, stainless, and nonferrous alloys. Oxyfuel, while less common for structural joining today, still shines for cutting, heating, and certain brazing applications.

Selecting a process means balancing skill level, environment, material, and productivity. For example, trainees tackling field repairs may lean on stick for its simplicity and portability. In a fabrication shop producing repeatable parts, solid wire processes offer speed and clean appearance with minimal slag. On thin sheet, a controlled short-circuit transfer can reduce burn-through. For intricate, high-appearance work or aluminum and stainless components, a precision-oriented approach with a foot pedal and filler rod can be ideal. Each method has a learning curve: electrode manipulation and arc starts for stick, wire stickout and gas coverage for wire-feed, and refined hand coordination for precision arc methods.

Consider these practical comparisons:

– Portability: Stick and flux-cored are resilient in remote or windy settings; solid wire and precision arc methods prefer stable, indoor conditions

– Cleanliness: Solid wire produces minimal slag; flux processes require chipping and brushing; precision arc can deliver exceptionally clean beads with proper prep

– Cost and consumables: Wire-feed can improve productivity; stick offers low equipment complexity; precision arc favors skilled hands and meticulous setup time

– Metals and thickness: Stick and flux-cored handle heavy sections; solid wire suits thin to medium; precision arc excels on thin, delicate, or high-value materials

Training should rotate through processes, not only to build versatility but to teach how each protects the puddle and controls heat. Shielding gas selection, wire diameter, electrode classification, and transfer mode all influence penetration and bead profile. Trainees learn to tune parameters rather than chase a single setting. When they understand why spatter increases or why porosity appears, they stop guessing and start diagnosing. The result is not just stronger joints but also informed decision-making in real job settings.

Tools, Materials, and a Smart Shop Setup for Trainees

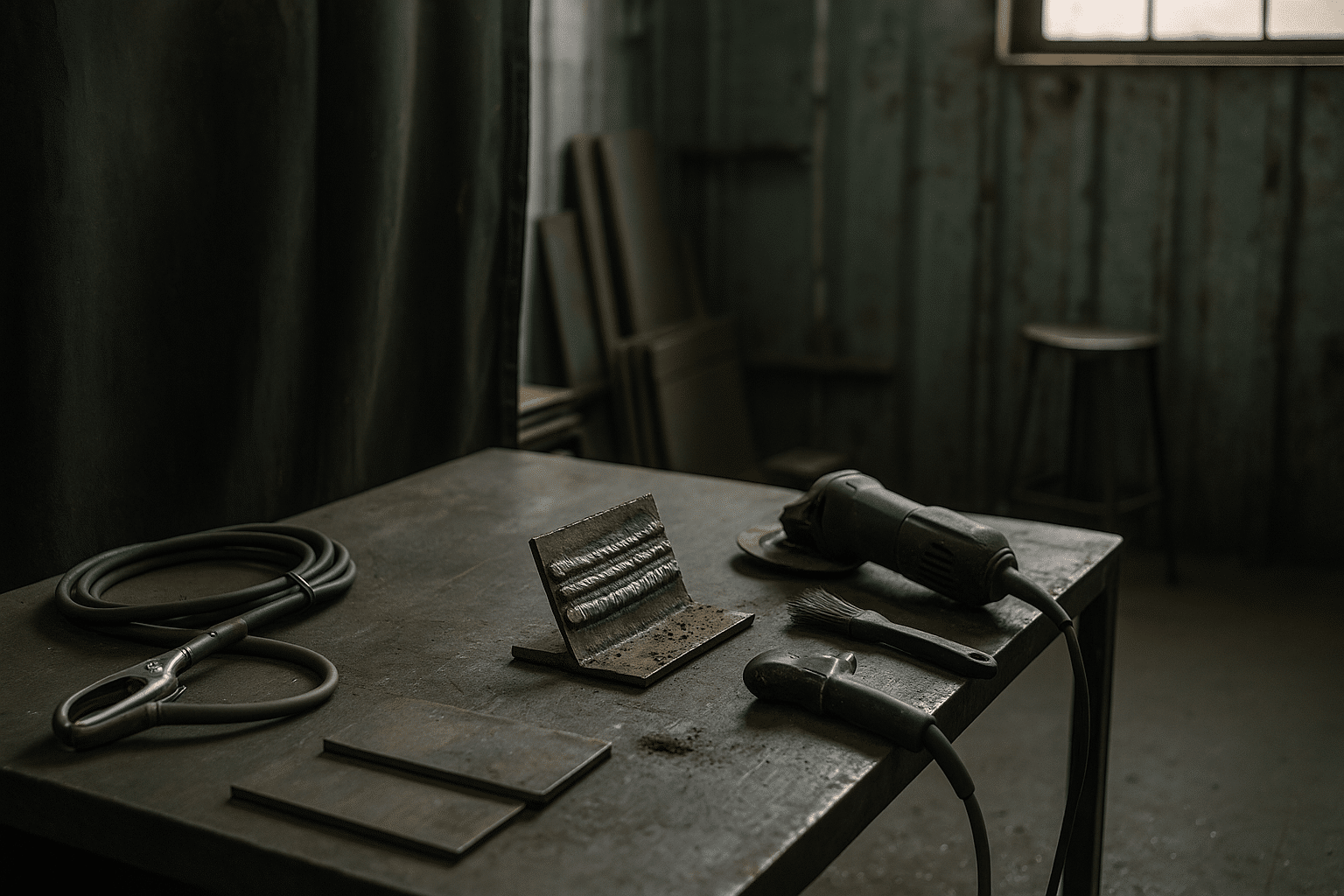

A thoughtful setup makes practice efficient and safer. Training spaces benefit from clear zones: clean tables for fit-up, dedicated areas for cutting and grinding, and fire-resistant welding booths that contain sparks. Good grounding reduces arc instability, so clean contact surfaces and robust clamps matter. Power sources vary by design; inverter units are compact and offer fine control, while traditional transformer units tend to be heavier and straightforward. Input power and duty cycle should match the expected workload; hitting a duty cycle limit mid-practice teaches planning as much as any lecture.

Consumables and prep drive results. Clean metal is non-negotiable: remove mill scale, rust, paint, oil, and oxide layers with grinders, flap discs, and brushes. Joint prep might include bevels for thicker sections, root openings, and land dimensions that help penetration without burn-through. Fit-up involves square edges, gaps within spec, and strategic tacks that resist distortion. Filler selection aligns with base metal type and service conditions. Storage prevents moisture pickup and contamination; keeping rods dry and wire spools covered reduces defects before they start.

Useful tools for learners include:

– Angle grinder with appropriate discs for prep and cleanup

– Measuring tools for layout: tape, square, center punch, scribe

– Clamps and simple jigs to hold parts square and steady

– Chipping hammer and wire brush for flux removal and inspection

– Non-contact thermometer or temp sticks to gauge preheat and interpass

Ventilation deserves special attention. Processes that produce higher fume rates call for capture at the source or strong directional airflow. Trainees learn to position their head to avoid the plume, monitor the workspace for lingering smoke, and recognize materials that require extra caution. Lighting quality matters too; a clear view of the joint line promotes accurate travel and reduces wandering bead profiles. Good housekeeping wraps it all up: coiling cables to avoid trip hazards, segregating scrap and consumables, and labeling material grades to prevent mix-ups.

Finally, introduce written guidance early. A simplified procedure sheet helps beginners replicate successful parameters: wire size, gas flow, amperage range, travel speed notes, and torch angles. Recording what works on flat plate versus vertical joints accelerates progress and turns practice into data-driven improvement. Over time, the shop becomes a learning engine, where each weld teaches the next one how to be better.

Training Pathways, Curriculum Design, and Certifications

There are multiple routes into welding, and each fits different goals. Structured school programs blend classroom theory with lab hours, often ranging from several months to a year, while apprenticeships extend on-the-job learning over multiple years with progressive responsibilities. Short intensives and bootcamps can jump-start fundamentals for career changers who need momentum quickly. The right path depends on schedule, budget, and the type of work you want to do—structural fabrication, maintenance, piping, or precision manufacturing.

A well-rounded curriculum covers more than just arc time. Core modules typically include safety standards, blueprint reading, measuring and tolerancing, basic metallurgy, thermal cutting, and inspection techniques. Process-specific labs move from flat to vertical and overhead positions, teaching settings, starts, stops, and tie-ins. Students track defects and corrective actions like a quality inspector, not just a technician. Introducing distortion control and welding sequence planning pays dividends the first time a real assembly must stay square within tight tolerances.

Assessment is hands-on. Practice coupons are prepared to a stated joint design and welded in specified positions and processes. Visual inspection precedes bend or break tests to validate internal soundness. Passing criteria rest on measurable acceptance limits—no significant lack of fusion, controlled reinforcement, and minimal discontinuities. Some trainees pursue code-based qualifications aligned to industry standards used in structures, pressure systems, or specialty fabrication. The paperwork matters: a qualification record documents which process, position, and material you are approved to weld. Employers rely on these records to assign tasks with confidence.

Planning your route benefits from clear milestones:

– Identify the industry you want to enter and the materials you’ll likely weld

– Choose a program that offers supervised lab time and progressive complexity

– Budget for PPE, consumables, and practice metal in addition to tuition

– Build a portfolio with photos of joint prep, parameter notes, and finished welds

– Schedule a qualification test when your instructor confirms consistent results

Support options can include scholarships, workforce grants, and employer sponsorships, depending on region and demand. Study groups, open lab hours, and mentoring accelerate progress by giving you eyes on your technique from multiple angles. The more structured your plan, the easier it is to measure growth and aim for the next rung—whether that is a new process, a tougher position, or a higher-consequence application.

Careers, Employability, and Lifelong Learning: Conclusion and Next Steps

Welding skills open doors across industries: construction sites where beams meet on windy mornings, fabrication shops crafting repeatable assemblies, shipyards shaping hulls, and energy facilities maintaining critical piping and equipment. Employers look for more than spark control; they seek reliability, safe conduct, and the ability to read drawings and think ahead. A portfolio of clean welds, neat fit-ups, and notes that show intentional parameter choices will often speak louder than a long resume. Versatility helps during economic cycles—being able to switch from shop production to field repair, or from carbon steel to stainless, keeps your opportunities wider.

Market realities vary by location, but certain themes are steady. Experienced pipe and alloy welders are often in demand due to the complexity and consequence of their work. Fabricators who can fit, tack, and weld with minimal rework reduce costs and gain trust. Inspection awareness is a differentiator; if you can anticipate what an inspector will measure, you can deliver it the first time. Soft skills round it out: communicating with fitters, coordinating with safety personnel, and documenting your work make projects run smoother and reputations stronger.

Your ongoing development plan might include:

– Mastering an additional process to increase flexibility and employability

– Learning to set up fixtures and control distortion on larger assemblies

– Practicing out-of-position welds to qualify for more job types

– Studying inspection criteria and acceptance limits relevant to your sector

– Exploring automation basics, including how to prep parts for robotic cells

Continuing education keeps you current as materials, procedures, and equipment evolve. Even small refinements—changing a contact-tip-to-work distance, adjusting travel speed by ear, or rethinking joint sequence—can reduce defects and boost throughput. Treat your training like a fitness plan: consistent sessions, targeted drills, and periodic tests. When you combine safe habits, a grounded understanding of physics, a clear grasp of processes, and thoughtful documentation, you become not just a capable welder, but a dependable problem-solver. That is the kind of professional who turns sparks into structures, one measured bead at a time.