Roof Replacement, Repair, and Installation: A Practical Guide

Outline:

– Understanding roof replacement: signs, timing, and what the process includes

– Roof repair services: when a fix is smarter than a full tear-off

– Roof installation: materials, methods, and ventilation that make roofs last

– Costs, estimates, and return on investment

– Maintenance, warranties, and a practical roadmap to long-term performance

Roof Replacement: When It’s Time and What to Expect

Think of your roof as the home’s shield: it takes the hits from sun, wind, rain, and debris. Replacement becomes wise when age and widespread wear outpace spot fixes. Typical lifespans vary by material and climate. Asphalt shingles often serve 15–30 years depending on quality, ventilation, and sun exposure. Metal commonly reaches 40–70 years, while clay or concrete tile can pass the half-century mark with proper underlayment and structure. Slate, installed correctly, can exceed many decades. Beyond age, the pattern and extent of damage matter more than a single leak.

Clear indicators often point toward replacement over patching:

– Curling, cracked, or missing shingles in numerous areas

– Granules filling gutters and downspouts, exposing bare shingle substrate

– Repeated leaks from multiple locations, not just one flashing point

– Sagging roof deck, soft or spongy feel underfoot, or visible daylight in the attic

– Persistent attic moisture, mold on sheathing, or rusted nails indicating long-term condensation

The replacement process typically includes a full tear-off to expose decking, allowing repairs that overlays would hide. Tear-off helps correct prior issues: insufficient intake/exhaust ventilation, missing drip edge, aging felt, or improperly lapped underlayment. In cold regions, self-adhered ice and water protection along eaves and valleys reduces ice dam risk. In wind-prone zones, nailing patterns, starter strips, and sealed edges are critical. Flashing around chimneys, walls, and penetrations must be reset or replaced; shortcuts here often cause future leaks.

Timing and preparation reduce headaches. Many crews prefer mild, dry seasons to ensure adhesives set and to minimize weather delays. Expect noise, vibrations, and short-term yard impact. A thoughtful contractor protects landscaping, covers attic contents if debris is likely, and manages disposal responsibly. Consider upgrades that add value during replacement: improved ventilation, higher fire ratings, or reflective surfaces in sunny climates that may aid cooling efficiency. Replacement is not just swapping materials; it’s a chance to rebuild the roof system—decking, underlayment, flashing, ventilation—with longevity in mind.

Roof Repair Services: Smart Fixes That Extend Roof Life

Not every problem justifies a full reroof. Repairs shine when the roof is within its expected lifespan and damage is isolated. Many leaks originate at details: flashings, skylights, plumbing vents, wall transitions, or valleys. A careful technician traces water paths, often starting in the attic, looking for stains, rusted nail tips, compressed insulation, and daylight around penetrations. Surface checks follow: lifted tabs from wind, broken tiles, loose ridge caps, cracked sealant, or deteriorated boots around vent stacks. Addressing these targeted issues can halt water intrusion and preserve the system longer.

Common repair services include:

– Replacing a handful of shingles and sealing exposed fasteners

– Reseating or re-bending step and counter-flashing at wall lines

– Installing new pipe boots or gaskets and sealing collars

– Reworking skylight curbs, adding ice and water membrane at frames

– Resetting ridge caps and correcting short fasteners or nail pops

– Rebuilding small sections of rotted fascia or soffit after leak resolution

Quality diagnosis matters. Infrared scans, moisture meters, or smoke testing (for ventilation issues) can reveal hidden trouble, though many fixes rely on trained eyes and methodical elimination. When storms strike, focus on uplift at the leading edges, impact bruising on shingles, displaced ridge vents, and debris damage. Ensure any temporary dry-in—tarping, cap nails, and sealants—is tidy and brief, then follow with a permanent repair before UV and wind degrade the patch.

Costs depend on access, pitch, material, and the complexity of details. Minor repairs often land in a lower three-figure range; intricate flashing rebuilds, steep roofs, or tall setups can climb into four figures. Prices vary widely by region and roof type, so expect an on-site assessment and a written scope that explains materials, methods, and any contingencies (e.g., hidden decking damage). Ask about repair warranties—short but meaningful coverage is common—and confirm that new components are compatible with existing materials. When the roof overall remains sound, strategic repairs are a practical, well-regarded way to buy time without overinvesting.

Roof Installation: Materials, Methods, and Details That Matter

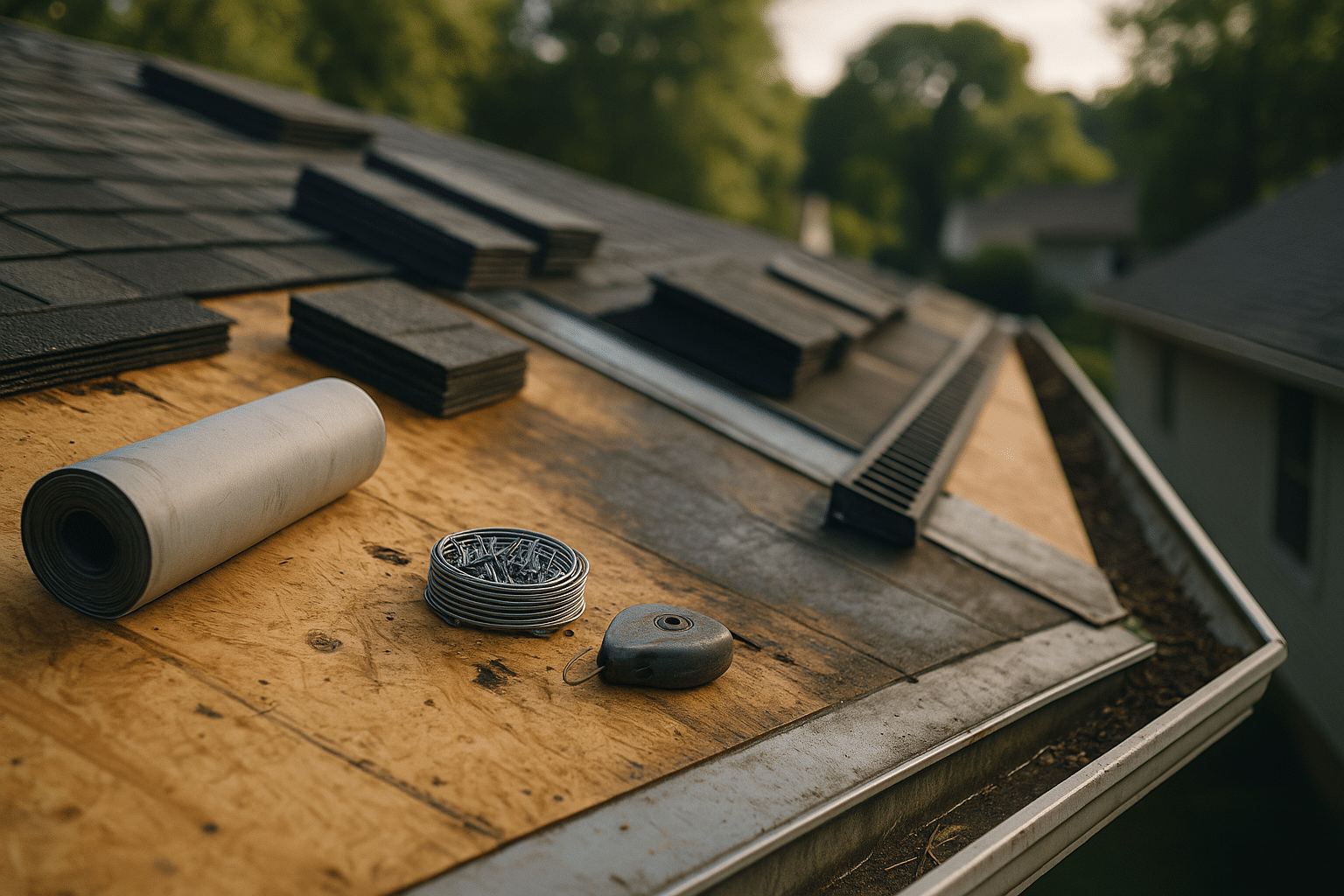

Installation quality transforms good materials into a durable system. A roof is layers working together: decking, underlayment, flashings, edges, vents, and the exposed surface. Start with the substrate. Plywood or OSB must be dry, flat, and adequately fastened. Underlayment choices include traditional felt and modern synthetics; the latter often resist tearing and wrinkling. In cold or leak-prone areas, peel-and-stick membranes at eaves, valleys, and penetrations add redundancy. Drip edge at eaves directs water into gutters; at rakes it guards against wind-driven rain.

Ventilation deserves front-row attention. Intake at the eaves plus balanced exhaust (ridge vents or other exhaust options) helps control attic temperature and moisture. Proper airflow can lower the chance of winter condensation and summer heat buildup that bakes shingles from beneath. Fastener selection and pattern matter too: correct length, placement above the adhesive line, and manufacturer-verified counts per shingle or panel row improve wind resistance. Valleys can be installed open (metal exposed) or closed (shingles lapped), each with precise techniques to move water efficiently.

Material selection should align with structure, climate, and aesthetic goals:

– Asphalt shingles: approachable cost, broad styles, straightforward installation

– Metal panels: notable longevity, excellent shedding, and reflective finishes

– Clay or concrete tile: high durability with significant weight; verify framing capacity

– Wood shakes or shingles: warm look, needs ventilation and regional fire considerations

– Slate: renowned lifespan; demands skilled installers and sturdy framing

Details elevate performance. Starter courses at eaves and rakes prevent wind lift. Kick-out flashing where a roof meets a vertical wall stops runoff from sneaking behind siding. Properly sized gutters and downspouts steer water away from foundations. For coastal or high-wind regions, additional fasteners and sealed seams help withstand gusts. In hot zones, reflective surfaces may moderate attic temperatures; in snowy climates, robust ice protection and unblocked intake vents reduce dam formation. Thoughtful installation blends science and craft, turning layers and lines into a cohesive shield that weathers seasons with confidence.

Costs, Estimates, and Value: Reading the Numbers Clearly

Budgeting for a roof means juggling size, complexity, material, labor market, access, tear-off, disposal, and potential decking repairs. Simple, low-slope planes cost less per square foot than steep, cut-up roofs with dormers, valleys, and multiple penetrations. Underlayment upgrades, ice barriers, ventilation improvements, and flashing rebuilds add cost but also resilience. In many regions, installed asphalt roofs often cluster in a mid-range price per square foot, with metal and tile typically higher due to materials, fasteners, and labor skill. Local codes, permits, and site logistics (like cranes for tile) also influence the total.

Expect a written, line-item estimate. It should list:

– Tear-off and disposal method (containers, recycling where available)

– Decking inspection protocol and per-sheet pricing if replacement is needed

– Underlayment types and coverage areas

– Flashing materials and locations (e.g., chimneys, walls, skylights)

– Ventilation plan (intake, exhaust, and calculated net free area)

– Material grade, profile, and color

– Warranty terms for both materials and workmanship

Numbers without context can mislead. A lower bid that omits proper flashing or ventilation might cost more later. Ask for proof of insurance and licensing where required, plus references and recent photos. Discuss schedule, daily cleanup, and how weather delays are handled. Clarify payment timing—reasonable deposits, progress draws tied to milestones, and a final payment after inspection protect both parties. As for value, real estate data frequently suggests that a new roof can recoup a meaningful portion of its cost at resale, while also improving curb appeal and buyer confidence. Energy savings may follow from reflective surfaces in sunny climates or tighter sealing around penetrations, though actual utility impacts depend on attic insulation, house design, and local weather. Aim for transparent scope rather than chasing a headline price.

Maintenance, Warranties, and a Long-Haul Game Plan

Once the last nail is set, ongoing care keeps small problems small. Seasonal checkups—especially after heavy wind or hail—help catch issues early. From the ground, look for lifted edges, missing pieces, or debris in valleys. In the attic, inspect for new water stains, musty smells, or frosted nails in winter that hint at condensation. Keep gutters clear so water exits quickly; overflowing gutters can back up under shingles and wet the deck. Nearby trees should be trimmed to avoid scuffing and leaf piles that trap moisture.

A simple maintenance rhythm works:

– Spring: clear gutters, check flashings, and confirm free airflow at soffit vents

– Summer: scan for UV wear, reseal minor exposed fasteners where appropriate

– Fall: remove leaves, confirm drainage paths, and prep for ice and snow

– After storms: document damage for insurance, apply temporary protection, schedule inspection

Warranties deserve attention. Material coverage typically addresses manufacturing defects for a defined term, sometimes prorated, and may require proof of proper installation and ventilation. Workmanship warranties cover the labor side—how components were installed and sealed. Some warranties are transferable once to a new owner, which can aid resale. Keep paperwork: contracts, product labels, color/lot information, and photos of underlayment and flashing before they’re covered. Improper add-ons—like satellite mounts that pierce critical areas—can jeopardize coverage, so coordinate any roof penetrations with qualified professionals.

Finally, think prevention. Ice dam risk drops with balanced ventilation and insulated attic floors that reduce heat loss. In hot climates, attic airflow and radiant barriers can temper peak temperatures, easing the load on cooling systems. A periodic professional inspection, even when nothing seems wrong, offers peace of mind and a fresh set of eyes on tricky details. Treat your roof as a system that rewards consistency: modest, regular care; tidy drainage; and documentation that proves the work was done right. With that approach, your roof quietly delivers what you count on—a dry, comfortable home season after season.